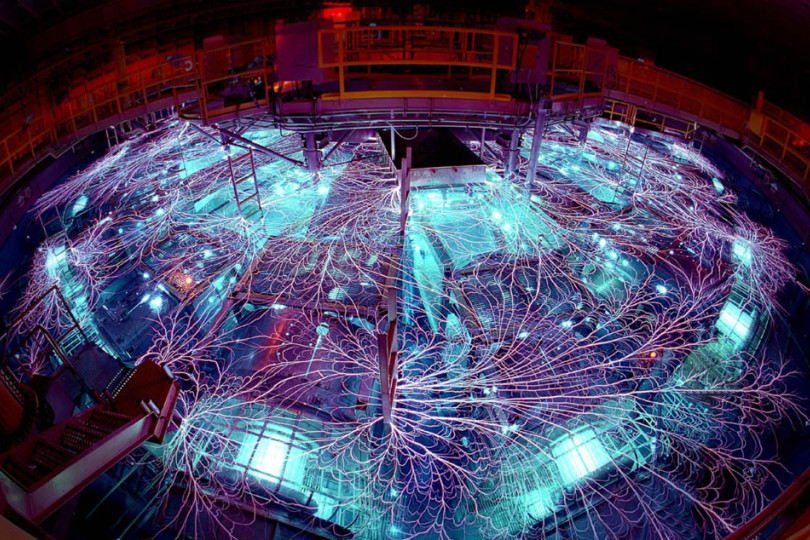

Arcs and sparks fly on the Z Machine, the world's most powerful electrical device, following its refurbishment by members of the NTL and Local 4. Photo courtesy Sandia National Laboratories

View Photo Gallery (8 photos)

When Boilermakers say they’re best in their craft, that they can build anything, it’s not an empty boast. From outfitting a ship in less than two weeks to contributing their skills to the first laser interferometer gravitation wave observatory, the union’s members are cutting-edge in their craft. Following is a retrospective of a few unique Boilermaker jobs that showcase the drive, skill and versatility of Boilermaker men and women throughout the past century.

Looking back over 100 years, Boilermakers were, even then, at the forefront of change and innovation when members helped to build the Los Angeles Aqueduct in 1913. The aqueduct is still operating safely today. The $23 million system of open ditches, reservoirs, dams, tunnels and siphons winds 270 miles from the Sierra Nevada Mountains to Los Angeles and uses gravity to move water and also generate electricity.

Members also contributed to the war effort in the United States and Canada spanning two world wars, building hundreds of combat and Liberty transport ships. Near the end of the Great War in 1918, members of Local 191 in Victoria, British Columbia, outfitted the ship War Chamehin in just 12 days at the assembly plant.

Gateway Arch

Fast-forward to the 1950s to the Gateway Arch in St. Louis. While Ironworkers erected the iconic monument, the lesser-known story is that Boilermakers did the front-end work. Members fabricated about 80% of the arch’s sections in Warren, Pennsylvania, with the large base elements constructed at Neville Island, near Pittsburgh.

Z Machine

In 2005, Boilermakers from the National Transient Lodge and Local 4 (Page, Arizona) updated the world’s most powerful electrical device, the Z Machine, located at the Sandia National Laboratory in Albuquerque, New Mexico. The Z Machine is a pulsed power accelerator able to create X-ray power output of nearly 290 trillion watts, or 80 times the entire world’s output of electricity, for short periods of time. Pulsed power is a term used to describe a process in which power is steadily accumulated, then rapidly released, resulting in the output of a large amount of instantaneous power.

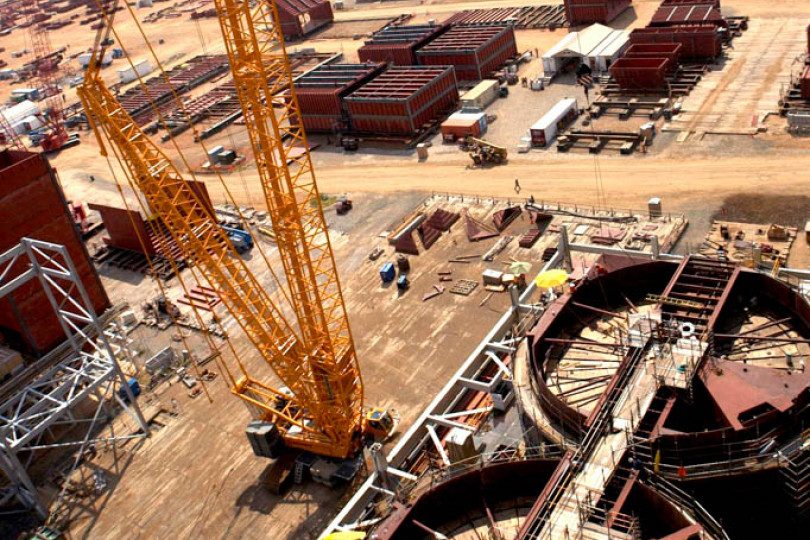

Ivanpah Solar

In more recent history, members from Local 92 (Los Angeles) were part of an innovative first—the Ivanpah Solar Electric Generating System in the Mojave Desert, about 40 miles from Los Angeles. Described as “inside out” or “reverse” boiler system, concentric circles of mirrors called “heliostats” reflect sunlight onto boiler tube walls, heating them to about 1,000 degrees Fahrenheit to create superheated steam. During construction in 2012, Boilermakers performed boiler work as well as erecting water storage tanks and the air-cooled condenser units that recover water from spent steam.

John W. Turk Plant

In 2013, Local 69 (Little Rock, Arkansas) and travelers completed the first U.S. ultra-supercritical John W. Turk Jr. Plant in Fulton, Arkansas. The design allows for higher temperatures and pressures than do conventional power plants by using chrome- and nickel-based super alloys in the steam generator, steam turbine and piping systems.

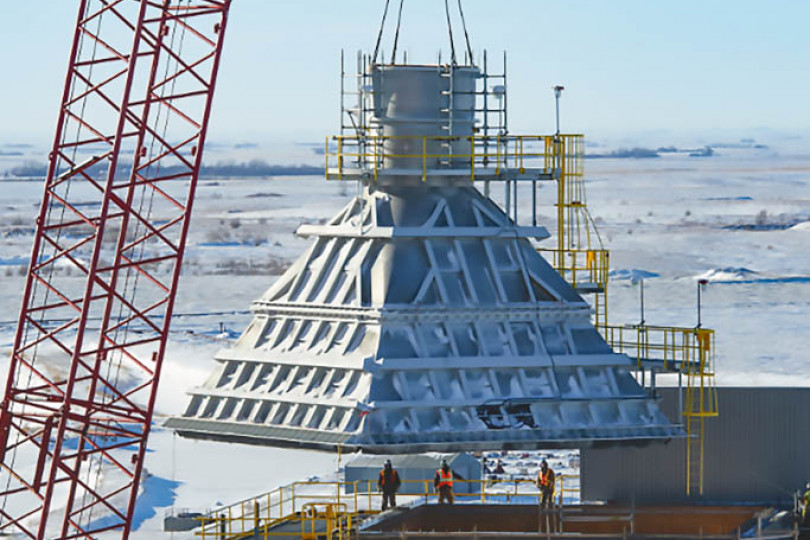

Boundary Dam

Boilermakers at L-555 (Winnipeg, Manitoba) and other members were part of the crew that built the world’s first use of utility-scale, post-combustion carbon capture, use and storage at SaskPower’s Boundary Dam Power Station in Saskatchewan. CCUS technology at the plant reduces greenhouse gas emissions by removing up to 1 million tons of carbon dioxide, equal to taking more than 250,000 cars off the road. Boilermakers’ role in that CCUS retrofit has led to continued advancements in CCUS, slow-but-steady adoption of the technology, and lowering costs for new CCUS builds and retrofits.

Modular HRSG

In 2017, members played a leading role in what’s believed to be the first ever U.S. heat recovery steam generator built as a complete modular unit then shipped to its final destination at Sewaren, New Jersey, to Public Service Electric and Gas. Boilermakers Local 5 Zone 197 (Albany, New York) led the union craft work on the HRSG and 20 air-cooled condensers, which made the trip down the Hudson River. Crews also constructed sections of the plant’s stack along with other assemblies. At Sewaren, Local 28 members (Newark, New Jersey) took part in offloading the HRSG, condensers and other components.

LIGO

Boilermakers helped prove Einstein’s theory of general relativity by building the stainless steel, spiral vacuum tubes at the Hanford Observatory in Richland, Washington. In 1992, Boilermakers from Local 242 (Spokane, Washington), Local 582 (Baton Rouge, Louisiana) and the National Transient Lodge manufactured and built 10 miles of specially fabricated, close-tolerance, stainless steel tubing to contain laser beams in a vacuum. By monitoring changes in those beams, scientists believed they could detect the presence of gravitational waves. After years of testing and upgrades, they were finally successful.