THE FUTURE OF COAL as a cheap, abundant, reliable energy source will be determined by how quickly reliable methods to capture and store carbon dioxide (CO2) emissions are developed.

The inconvenient truth for the coal industry is that burning one ton of coal generates nearly three tons of CO2, making coal an easy target for those looking for a quick fix for global warming. As recently as 2005, there was talk of building as many as 100 new coal-fired power plants. But uncertainty over how the government will regulate emissions ended or stalled most of those projects.

Fortunately, carbon capture and storage (CCS) technology is advancing rapidly. One promising method is the chilled ammonia process used in AEP’s pilot project at the company’s Mountaineer plant in West Virginia. Capturing CO2 requires using more energy than a traditional coal-fired plant (raising cost), but early results suggest the chilled ammonia process may be more energy-efficient than other processes, and therefore more economical.

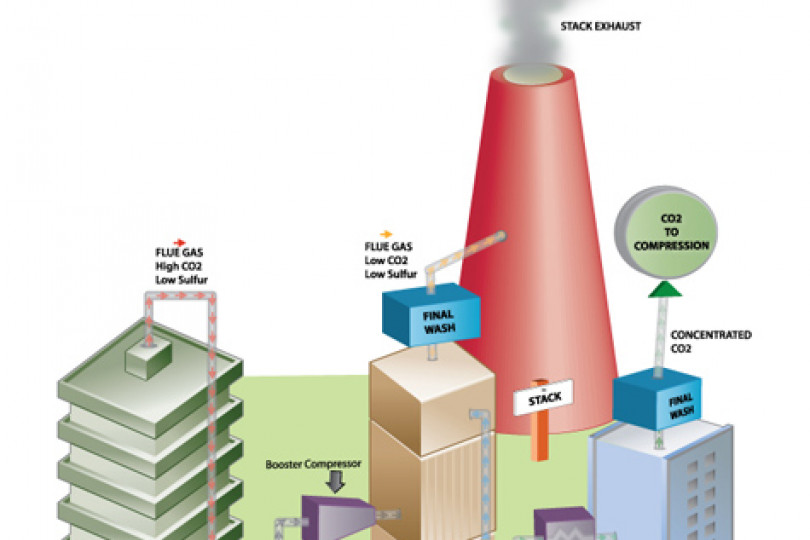

In this process, flue gas is run through a chiller which takes it down to -35o F before it enters the absorber vessel. In the absorber, the flue gas reacts with a slurry containing ammonium carbonate. The CO2 in the flue gas reacts with the ammonium carbonate to form ammonium bicarbonate.

With about 90 percent of its CO2 removed, the flue gas continues to the stack for emission. Meanwhile, the ammonium bicarbonate created by the absorption goes into a regenerator, where it is heated, separating the CO2 from the ammonium carbonate.

The ammonium carbonate is then returned to the absorber to capture more CO2, while the CO2 travels to a scrubber vessel where excess ammonia is removed.

Then the CO2 is compressed and pumped into a geologic reservoir a mile-and-a-half underground.

Because the chilled ammonia process utilizes post-combustion vessels, scrubbers, and ducts — traditional Boilermaker work — its widespread application could generate a lot of Boilermaker man-hours. The same is true for other CCS systems currently in development.

Future issues of the Reporter will provide insights into some of the new technologies Boilermakers may be working on over the next few decades.