Standing in front of the massive new Prairie State Energy Campus power plant are, l. to r., Rick Eller, L-363 BM-ST; Mike Rother, PSGC director of contracts and industrial relations; and John Hoerner, L-363 member and Boilermaker general foreman.

View Photo Gallery (9 photos)

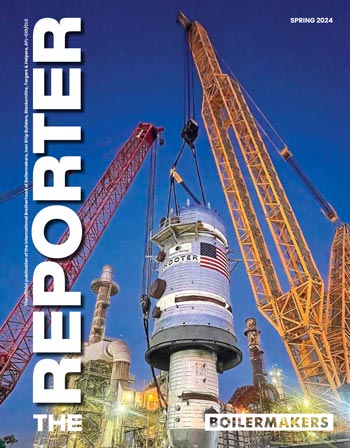

Massive project brings five million man-hours to Local 363 jurisdiction

THE LARGEST COAL-FIRED power plant currently being built in the United States is taking shape in southern Illinois, and Boilermakers from across the country are playing a leading role in its construction.

The $4 billion, 1,600-MW Prairie State Energy Campus is located about 50 miles southeast of downtown St. Louis in Lively Grove, Ill. The campus includes twin 800 MW supercritical power generation units and an on-site coal mine with 200 million tons of recoverable coal — enough to fuel the plant for 30 years.

“The Boilermakers have been the key to getting us to where we are, and are the key to getting the plant done on time.”

— Peter DeQuattro, CEO - Prairie State Generating Co.

According to Peter DeQuattro, president and chief executive officer for Prairie State Generating Co. (PSGC), the facility will be one of the cleanest coal-fired power plants in the country, with overall emissions half that of comparable plants and carbon dioxide emissions 15 percent lower. A local fuel source, supercritical technology, and the application of best-available emission controls combine to reduce the plant’s environmental footprint.

Peabody Energy originally developed the concept for the campus. The company has a five percent ownership; eight municipal and cooperative power supply organizations own the remaining 95 percent. The facility will serve over 2.5 million customers in eight states and contribute over $785 million in regional economic activity each year.

PSGC has overall responsibility for constructing the campus and will also operate the facility. Bechtel Power Corporation is the prime contractor for the power plant, with signatory contractors B&W, Sterling Boiler, and Fisher Tank Co. also involved. The plant is being built entirely with union labor.

One thousand Boilermakers work on project

THE PROJECT SCOPE is truly enormous. Over 4,000 people are involved in constructing the plant, including more than 1,000 Boilermakers working under the jurisdiction of Local 363 (E. St. Louis, Ill.). The campus covers over 2,400 acres of surface with approximately 35 square miles of an 8-foot-thick coal seam located directly beneath the plant and the surrounding area. Five hundred acres are fenced at the plant and 200 at the mine.

PSGC’s DeQuattro said the Boilermakers’ scope of work is big — an estimated five million man-hours. In addition to building the two massive, B&W supercritical boilers, and performing extensive tank fabrication, Boilermakers are constructing the advanced emission control system that includes nitrous oxide scrubbers, selective catalytic reduction, limestone scrubbers, and wet and dry electrostatic precipitators.

“[The emission system] takes up over 50 percent of the plan area of the power block,” said DeQuattro, “and represents over $1 billion in cost.”

The schedule allows for 50 months from full-notice-to-proceed to commercial operation of unit 1, with 19 months from first pressure part erection to hydro (water-testing boiler components for leaks). Unit two is scheduled to go on line eight months after unit 1. Over the life of the project, Boilermakers will make over 70,000 tube welds, complete numerous heavy lifts, and build over eight million gallons of tank capacity.

Members complete 32,000 field welds without a leak

MEETING THE AGGRESSIVE project schedule has required an extensive prefabrication effort, according to DeQuattro. Bechtel Power, B&W engineers, and the Boilermakers began work early in the process. Boilers were purchased, redesigned, and delivered to a 50-acre lay-down area at the site. December 2010 marked a critical milestone — completing the unit 1 boiler hydro.

“The Boilermakers have been the key to getting us to where we are, and are the key to getting the plant done on time,” DeQuattro said. “The 19-month planned duration of first pressure parts to hydro . . . was only made possible by extensive prefabrication and the efforts of the Boilermakers.”

Said L-363 BM-ST Rick Eller, “Boilermakers have done their duty, made their welds to meet a hydro deadline that just four months prior seemed impossible. I couldn’t be prouder of my members. They are doing a fantastic job. However, we couldn’t get through a job of this size without the help of Boilermakers and their business managers from all over this country. We appreciate all of them coming here and working so hard.”

Not only are members working hard, they are working safely. A review in Nov. 2010 showed a total of 5.3 million man-hours worked (by all crafts) without a lost-time accident — a new safety record for PSGC.

Michael P. Rother, director of contracts and industrial relations for PSGC, said, “Under the leadership of Local 363, the Boilermakers provided the necessary skilled welders, riggers and mechanics — from nearly every state in the nation — to successfully take on the many challenges of our power plant project. It was the Boilermakers’ commitment to excellence and their ‘do it right the first time’ attitude that allowed the welders to achieve an awesome quality performance on unit 1 boiler hydro — 32,000 field welds without a leak. This outstanding feat, and the fact that the overall Boilermaker weld rejection rate for the project is 1.15 percent, is simply remarkable, and a true testament of the skills and character of the Boilermaker craft.

“The high level of performance by the Boilermakers will ultimately ensure reduced costs to our owners and the longevity of our plant operations after the commissioning of our units,” Rother added.

“[Completing] 32,000 field welds without a leak is...simply remarkable.”

— Michael P. Rother, Dir. of contracts and industrial relations - Prairie State Generating Co.

International Rep Tony Palmisano reported that with such a large-scale project some job issues are inevitable, but they have been effectively handled. “I’m extremely appreciative of the way the owner, contractor, and union have collectively addressed these issues in a true tripartite fashion.”

Great Lakes IVP Lawrence J. McManamon described the Prairie State project as “a once-in–a-lifetime project. Opportunities like this are unique,” he said. “The safety and craftsmanship of the Boilermakers has been extraordinary. Once again the Boilermakers are demonstrating that we are the best in the industry.”

The first unit of the Prairie State Energy Campus is expected to go online by Dec. of 2011, the second by the summer of 2012.

Local 363 is a construction lodge chartered in 1903.